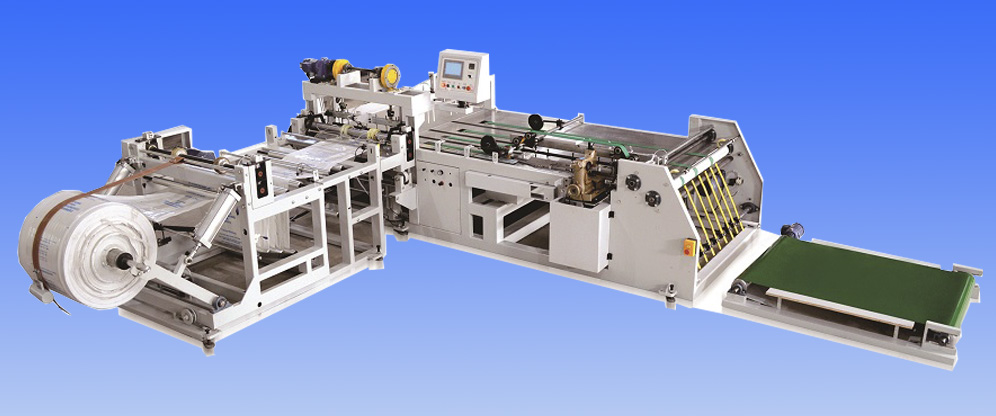

Max Fabric Width 800mm

Max Fabric length 1200mm

Max. Sewing Speed 30-35pcs/min

Unwinding and Take-Up Unit

The Unwinder is equipped with Auto Elevator to load fabric automatically, easy operation. EPC equipped, dancing Roller control Tension, Inverter control unwinding speed.

l Unwinding frame:800mm

l With automatic correction function

l Frequency conversion: the inverter uses ABB brand

l Conveying motor power: 0.75Kw

Cutting Unit

Servo Motor controls feeding, Double Cam design for stable running of Heat Cutting; Pneumatic controls Cold Cutter. Mark Sensor to detect printed fabric, Servo control feeding length for non-printing fabric, achieves accurate cutting. Vertical & Heat Cutter with bag mouth open system. PLC & Inverter control cutting speed, sync control.

Servo motor: 1Kw Japan

l Servo controller: 1Kw Japan

l Color standard sensor adopts German SICK

l motor power for cutter: 0.75Kw

l Inverter 0.75Kw

l Equipped with an automatic opening device (separate the bag mouth when hot cutting)

Manipulator of Transfer unit

Servo Manipulator transfers woven bag after cutting, Servo motor control the Manipulator, achieves precision transferring, and makes sewing quality.

l Servo manipulator 1set Domestic

l Servo motor: 0.37Kw Japan

l Servo controller: 0.37Kw Japan

Sewing & folding Unit

Adopts Japanese Newlong Sewing Head, achieves high-speed & high-quality sewing. Equipped with single folding device, Inverter control sewing speed, PLC & Inverter for sync control

l Japan Newlong sewing machine: DN-2HS

l Sewing motor power: 0.75Kw

l Sewing frequency converter: 0.75Kw ABB

l Conveying motor power: 0.75Kw

l Conveying frequency conversion power: 0.75Kw

l Folding device: single fold

l It is equipped with a slitting device for Sewing thread.

Bag Collecting Unit

Sensor & PLC control, Auto Counting, Stacking & conveyor-belt advancing

l Imported conveyor belt from the Netherlands

l Photoelectric detection device

l Collecting Bag motor power: 0.37kw

Machine Feature

l New Long sewing machine for stable and long-life operating

l Servo controlling for cutting accuracy

l High-speed cutting and sewing

l Heat cutting with Bag Mouth Open System equipped

l Edge Position Control (EPC) for Unwinding

l Manipulator to transfer the Woven Bag after cutting

l PLC Control, Digital Display for Operation Monitor and Operation Setting

Equipment environmental conditions

l Air temperature:-5℃~ +40℃

l Altitude:≤1780米

l Use place: indoor

l Power requirements:3 phase AC 380 V ± 10%; 50Hz±2 Hz

l Air source requirements: ≥0.6Mpa Air volume: 0.2 m3/min

| Max Fabric Width | 800mm |

| Max Fabric length | 1200mm |

| Max. Cutting Speed | 40-60 pcs/min |

| Cutting Length | 300-1300mm |

| Cutting Accuracy | ±1.5mm |

| Max. Sewing Speed | 30-35pcs/min |

| Stitch Range | 3.6-8mm |

| Folding Width | 20-40mm |

| Power connection | 13.5HP |

| Machine weight | About 2T |

| Dimension (lay-out) | 5880x3880x1360mm |

HOME

HOME