Max. printing area(L x W) 1250 x 720mm

Max. Bag making size (L x W) 1250 x 800mm

Printing Speed 80-120m/min

This model can print up to 12 colors 6+6, please specify in advance if you have other requirements.

- Single-Pass, two side printing

- High Precision Color Positioning ,Direct Printing for Color (image) Printing

- No-stop Fabric Roll Switch-over

- Easy to change Printing Roller for differ size printing

- Edge Position Control (EPC) for Winding and Unwinding

- Auto Recirculation/Mixing System for Paint Mixture

- Center Oven for complete drying

- Main Motor Driving with Inverter Control, sync printing

- PLC Operation Control, Digital Display for Operation Monitor and Operation Setting

|

Qty |

Description |

|

|

|

|

1set |

Elevator for Fabric Loading Electric auto lift for 1ton

|

|

1set |

Unwinding and Take-Up Unit Dancing Rollers to control the tension Two working position unwinding (one standby, one unwinding) Sensor control No-Stop Fabric Roll Switch-Over EPC for Unwinding Corona System for two-side treatment |

|

1set |

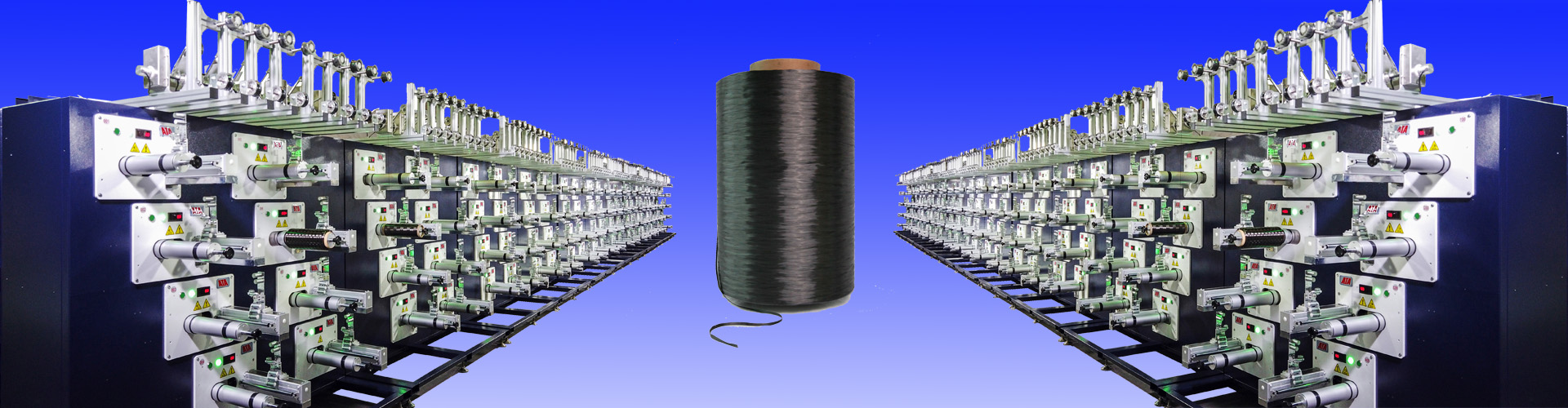

Full Auto Printing Unit for First Side Printing (Center Drum) Direct printing on Woven Fabric for Color (image) Printing Fabric Guiding Unit equipped for feeding 1 pc of Center Drum, 6 sets of Printing Units surround it for quality printing 6 sets of Printing Roller, Anilox Roller and Rubber Roller for 6 Colors 6 sets of Pre-blower for each printing unit 6 sets of Auto-Recirculation/Mixing System for Paint mixture (Air Pump) After first side printing, fabric will go through Center Oven for complete drying Reducer connected with Second Printing Unit with sync driving |

|

1 set |

Full Auto Printing Unit for Second Side Printing (Center Drum) Direct printing on Woven Fabric for Color (image) Printing Fabric Guiding Unit equipped for feeding 1 pc of Center Drum, 6 sets of Printing Units surround it for quality printing 6 sets of Printing Roller, Anilox Roller and Rubber Roller for 6 Colors 6 sets of Pre-blower for each printing unit 6 sets of Auto-Recirculation/Mixing System for Paint mixture (Air Pump) After second side printing, fabric will go through Center Dryer for complete drying Reducer connected with First Printing Unit with sync driving Main Motor equipped for driving |

|

1set |

Center Oven for Drying Two parallel Heaters equipped for separation drying of two sides Airtight design to save power Adjustable type for different circumstances Fan and Heater for complete drying |

|

1set |

Rewinder Dancing Roller to control winding tension Protection Unit for emergency stop EPC equipped for Rewinding Center winding with Auto Roll-Changing Device |

|

1set |

Electrical Control Panel 1 set of ABB inverter for Unwinding 1 set of ABB inverter for Winding 1 set of ABB inverter for Main Motor |

|

1set |

Air Compressor: 5.5HP |

| Color | 6+6, 6+5, 6+4 or less, Color Printing |

| Max. bag width | 800mm |

| Max. printing area(L x W) | 1250 x 720mm |

| Max. Bag making size (L x W) | 1250 x 800mm |

| Printing Speed | 80-120m/min |

| Power connection | 39HP |

| Machine weight | About 20T |

| Dimension (lay-out) | 20000x2800x4000mm |

HOME

HOME